ALPHA DIRECT - TPU blown / cast film product

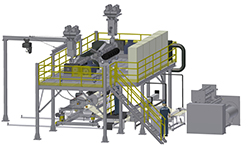

Alpha Direct blown / cast production lines deliver both performance and flexibility, producing a high quality end product.

Whether for TPU films or vacuum formed rigid or flexible end products Alpha Marathon is able to design a complete line system best suited to your process.

Direct extrusion process provides a more efficient process achieving higher line speeds utilising a series of heated and chilled rollers to maintain proper temperature management of the web.

Alpha can also integrate additional lamination options should it be required to provide further product flexibility.

As all Alpha Marathon equipment is designed and engineered in house many custom options may be available for new product developments.

Blown film features:

|

Model |

ADB16 |

|

Layers |

2 |

|

Max. Film Layflat (mm) |

1600 |

|

Film Thickness(micron) |

25 ~ 100 |

|

Max. Output (kg/hr) |

250 |

|

materials |

TPU, LDPE |

Cast film features:

|

Model |

ADC16 |

|

Layers |

2 |

|

Max. Film Layflat (mm) |

1600 |

|

Film Thickness(micron) |

15 ~ 100 |

|

Max. Output (kg/hr) |

450 |

|

materials |

TPU, LDPE |

End Product range:

- Water proof clothing

- Disposable diapers

- Tent industries

- Boat industries

- Ice Bags

- Sealing weapons

- Bullet proof glass

- Fire proofing insulation