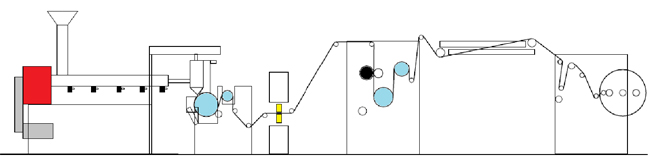

ALPHA CPP - Cast Polypropylene Film Lines

Alpha Marathon’s Cast polypropylene film lines are available in 3 and 5 layers and each line is capable to producing a variety of structures.

Line supplies with latest technology for Screw, Feedblock and Die design to improve quality and increase line output to provide the flexibility to meet the needs of our customers.

Alpha Marathon’s CPP film line designed with special features to improve operation process, reduce downtime and save in energy cost.

Optimized Screw design to ensure excellent mixing and proper melt required for CPP final product with lowest gel counts.

Fully Automatic die and gauge system provide uniform thickness cross the web.

Alpha Marathon’s special Softbox and Airknife incorporated with dual chamber vacuum box are working great to provide best crystal clear CPP film. Alpha Marathon’ CPP line comes with high quality Corona Treater unit to ensure final product has proper surface energy for printing, either one side or both side accordance to customer’s need.

Trims are directed to core layer as fluff to ensure zero waste from production line.

Final product application:

- Bread Packaging

- Dry food packaging

- Twist wrap, Candy/confectionery Wrap

- Floral Wraps

- Textiles packaging

- Medical and Hygiene film

- Lamination films for surface protection with barrier properties

- Metalized film for snack packaging

- Retort Packaging

- Deep Freeze application

|

Model |

CPP15 |

CPP20 |

CPP25 |

CPP30 |

CPP40 |

|

Finish Film Width |

1500 mm |

2000 mm |

2500 mm |

3000 mm |

4000 mm |

|

No. of Layers |

3 |

3 |

3,5 |

3,5 |

3,5 |

|

Extruder sizes (mm) |

65, 75, 90, 120, 150 |

||||

|

Roll Diameter (mm) |

600,1000 |

600,1000 |

1000 |

1000 |

1000 |

|

Air Shaft Dia. (mm) |

76,152 |

76,152 |

152 |

152 |

152 |

|

Winder Type |

Turret |

Turret |

Turret |

Turret |

Turret |

|

Thickness (micron) |

15-120 |

15-120 |

15-120 |

15-120 |

15-120 |

|

Typical Raw Material |

Homo and CoPolymer PP |

||||

|

Max. Speed (mpm) |

300 |

300 |

300 |

300 |

300 |

|

Max. Output (kg/hr @ 20um) |

520 |

680 |

810 |

1140 |

1300 |